A Research on the Compact Spinning for Long Staple Yarns

Pinar Çelik,

Hüseyin Kadoğlu

Ege University, Department

of Textile Engineering

35100 Bornova, Izmir, Turkey

E-mail: pcelik@textile.ege.edu.tr

hkadoglu@textile.ege.edu.tr

Abstract

Compact spinning produces a new yarn structure, as the edge fibres are incorporated into the yarn due to the elimination of the spinning triangle, so that the harmful effects of the spinning triangle on yarn characteristics are eliminated. The compact yarns possess less hairiness, better strength, better uniformity and lower values of thick & thin places and neps compared to the conventional ring-spun yarns. In this article, some quality parameters of long-staple compact yarns are compared to those of long-staple conventional ring yarns.

Key words: compact spinning, conventional ring spinning, spinning triangle, worsted spinning, yarn hairiness, yarn tenacity.

n Introduction

Compact spinning technology has been gaining much more interest since its first commercial introduction at ITMA-Paris in 1999. These spinning machines have been installed in several spinning factories all over the world. Compact spinning is a modified ring spinning process which has special advantages, and can be used in both short- and long-staple yarn spinning areas.

The zone between the line of contact of the pair of delivery rollers and the twisted end of the yarn is called the spinning triangle. In this zone, the fibre assembly contains no twist. Edge fibres splay out from this zone, and make little or no contribution to the yarn strength. The spinning triangle is the critical weak spot of the spinning process [1].

The spinning triangle prevents the edge fibres from being completely incorporated into the yarn body. However, in compact spinning, the drafted fibres emerging from the nip line of the front roller of the drafting arrangement are condensed in a line [2].

Ring-spun yarn is not perfect. If the enlarged view of ring spun yarn is examined, it is easy to see that the integration of many fibres is poor, and they therefore make no contribution to yarn strength. In other words, if all fibres could be completely integrated in the yarn, both strength and elongation could in turn be further enhanced. It is thus obvious that even ring-spun yarns are not yet ideal as regards yarn structure [3].

The development of the compact spinning process began with the desire to achieve a significant step for yarn quality by influencing the spinning triangle (Figure 1). This work is focused on achieving higher yarn strength and a reduction of yarn hairiness, especially on eliminating the longer hairs which have a particularly bad influence on the further process [4].

Many researchers have described the technical principles of compact spinning and the more organised structure without peripheral fibres and with a better twist distribution. The compact yarn shows higher strength, reduced hairiness, and improved evenness. (Artzt, 1997 [5]; Olbrich, 2000 [4]; Stalder, 2000 [3]). M. Nicolic et al. [10,11]are among those researchers who investigated the similarities and differences in the structural, mechanical/physical and texturing properties of ring-spun yarns of 20 tex, manufactured from various yarn blends (combed cotton, PET, CV, PA) from the same sliver, employing compact spinning on the Fiomax 1000 and Fiomax E1 ring-spinning machines from Suessen. According to their test results, the qualities of compact yarns are better than those of ring-spun yarns [10,11].

The compact spinning process produces a new yarn structure which approaches the ideal staple fibre yarn construction even more closely. This has positive effects on raw material use, productivity, downstream processing, and on the product appearance [5].

The end breaks in spinning are approx. 50% fewer, which permits the reduction of the number of fibres in the cross-section, or to spin a finer yarn count. Reducing the possibility of the number of fibres in the cross-section allows for the use of lower-priced tops with coarser fibres [6].

In compact yarns, fibres are uniformly oriented and joined into the yarn right after the end of the drafting arrangement. Therefore, better tenacity, elongation, and hairiness properties can be ensured. The better tenacity properties of compact spun yarn provide opportunities to work with lower twist coefficients, resulting in an increase in production rate, and also better handling properties of the end-product.

Another advantage of the compact spun system is the fly and dust reduction as an effect of condensation. The cleaning requirement is reduced when compared to conventional ring spinning frames.

Compact spun worsted yarns also have the advantages of better quality properties and different surface specifications, which will help to improve further processing and increase their production rate [7].

When using compact yarns, and allowing for the same level of warp breaks, the consumption of sizing agents can be reduced. This provides considerable cost savings in sizing and de-sizing. The same is true for warp breaks in weaving. Compact yarns permit better yarn regularity and the formation of a smoother yarn surface. This reduces the number of end-breaks by 30-50%, and leads to savings in the weaving department with significant improvements in efficiency, in the range of 3-5% [6].

Industrial trials of compact yarns have revealed a fly reduction of 1/3 on the knitting machine. If one considers the number of faults due to knitted-in fly lumps as a percentage of the total fault count in knitting, there is distinct cost-reducing potential here with the use of these yarns. [5] With their increased yarn strength and reduced formation of fluff, compact yarns permit higher machine efficiency to be achieved, and therefore production on knitting machines can achieve a reduced ends-down rate, fewer interruptions and fewer fabric faults [8].

n Experimental

Materials and methods

In this study, we compared the yarn properties of compact yarns and the conventional ring spun yarns in terms of yarn hairiness (the number of protruding fibres on the yarn’s surface), yarn evenness, tenacity and elongation (%).

The experimental work of this study was conducted on a Long Staple Tester PR 135 ring spinning machine by using four different raw materials. Compact spinning has some advantages for both weaving and knitting. The 100% wool and 45% wool/55% PET materials were spun with weaving twist factors, and the 50% wool/50% PAN and 100% PAN materials were spun with knitting twist factors. In the market, acrylic yarns and their blends with wool are usually preferred for knitting products; on the other hand, wool and wool/PET worsted yarns are usually preferred for woven products.

On the ring spinning machine, the option of spinning compact yarn by adding compact spinning equipments (Suessen EliTe®) was available. It was thus possible to compare both the systems under identical machine conditions. Table 1 shows the experiment plan. After the spinning trials, the physical properties of each yarn sample were measured, and the measurement results of conventional ring yarns and compact yarns were compared to each other.

Yarn evenness (CV%), thick & thin places, nep values and yarn hairiness values were measured with an Uster Tester 3 (the measurement length was 400 m/bobbin). Yarn tenacity (cN/Tex) and elongation at break (%) were measured with a Statimat M. In addition, yarn hairiness was also measured with a Zweigle G565 yarn hairiness tester (the measurement length was 100 m/bobbin).

n Results and Discussion

The compact spun yarns had better yarn property values - irregularity, thinand thick places, nep values, yarn hairiness, tenacity and elongation at break (%) - than the conventional ring spun yarns for all material types. The 100% wool yarn hairiness test results were given in Table 2 as an example.

The results obtained from the laboratory testing of yarn samples were statistically evaluated by using SPSS software. Variance analysis was applied, and by using F values we tried to find out if there was any statistically significant difference between the yarn quality data of conventional and compact yarns. (The details of the test results, statistical results and F values are found in Çelik [12]).

Yarn evenness

When we examined the yarn evenness of 100%-wool yarns, the Uster CV% and the thin place values of both compact and conventional yarns were found to have a statistically significant difference for a significance level of α=0.05 for both 19 tex and 25 tex yarn counts (Figure 2). On the other hand, the differences of the two spinning systems in terms of the mean numbers of thick places and neps of 100% wool yarns were found to be statistically significant for only the fine yarn count, 19 tex. The Uster CV%, the thin and thick place values of compact and conventional 45% wool/55% PET yarns were found to have a statistically significant difference for 19 tex (Figure 3).

When we examined the yarn irregularity CV%, there was a statistically significant difference between the compact and conventional ring yarns which was produced with 50% wool/50% PAN for both two yarn counts, 25 tex and 36 tex, and all twist factor levels; but the differences of two systems were found to be statistically significant in terms of thin and thick places for fine yarn count only, 25 tex (Table 3).

The differences of compact-spun and conventionally-spun yarns which were produced with 100% PAC, in terms of the Uster CV% and I.P.I. values (thin & thick places and neps) were not found to be statistically significant, but the compact yarns’ Uster CV% values are lower than the conventional ones.

Yarn tenacity and elongation

For all material types, the tenacity and elongation (%) values of compact yarns were higher than those of the conventional ring yarns. But the evaluations of statistical analysis results of the difference of two systems changed according to the types of material.

When we examined yarn tenacity, there was an important difference between compact and conventional ring yarns which were produced with 100% wool for two yarn counts and all twist levels. The compact-spun yarns’ tenacity and elongation (%) values are higher than the conventional ones, but at the high twist level, the elongation values of compact and conventional ring yarns were very similar.

On the other hand, when we examined 45% wool/55% PET yarns, the differences of tenacity values were found to be statistically significant only for 25 tex yarns (Figure 4). In addition, there was no statistically significant difference between the compact and conventional ring yarns which were produced with 45% wool/50% PET for elongation (%) values, and those for both yarn counts.

There was a statistically significant difference between the compact and conventional ring yarns produced with 50% wool/50% PAN in terms of yarn tenacity for both yarn counts, 25 tex and 36 tex. However, the differences in the two spinning systems were found to be significant in terms of elongation (%) values for 25 tex yarns only.

When we examined 100% PAN yarns, there were statistically significant differences between the two spinning systems for low twist levels only in terms of tenacity and elongation at break (%) (Figure 5).

Yarn hairiness

When we examined yarn hairiness values, the compact yarns’ hairiness values were very low, even for yarns with low twist levels for all material types. For example in 36 tex yarns produced with 50%wool/50% PAN, the compact yarns’ S3 values were found as 1115 for αtex=2530, and 769 for αtex=3160. On the other hand, the classic yarns’ S3 values were found as 2563 for αtex=2530, and 1643 for αtex=3160. According to statistical analyses, statistically significant differences were found between compact and conventional ring yarns for all material types in terms of Uster hairiness and Zweigle hairiness.

The hairiness properties of yarns were measured using a Zweigle G565 hairiness tester which classifies hair length on yarn surfaces. The hairiness measurementsshow that there is a significant reduction in all hair length classes on the compact yarn’s surface. This improvement was found to be promising for the compact yarn’s subsequent textile processes. For example, knitting yarns are generally spun with low twist values which provide softer and hairier yarn. Although high hairiness of a yarn is accepted as an advantage for some knitting yarns, it is also a disadvantage because it is a source of pilling. The S3 code, which defines the total number of hairs of 3mm length and above, exhibits a hairiness level that causes the pilling problem. When compact and conventional yarns are compared, it is seen that compact yarns have lower S3 values than conventional ring yarns (Figure 6). In addition, yarn hairiness is very important for the weaving preparation and process, so compact weaving yarns have more advantages than conventional ring yarns in terms of yarn hairiness and yarn strength.

According to these results, although the compact yarns are produced with low twist levels, their yarn hairiness values are lower than the conventional ring yarns. So we can produce softer products with compact yarns when we compare them with conventional ring yarns. In addition, low twist level means high production.

n Summary

In this experimental work, some of the yarn properties of compact spun and conventional ring spun yarns were compared. We investigated the effects of spinning technique and material type on the properties of yarn.

The compact yarns covered in this study showed better yarn properties than conventional ring yarns. It has been demonstrated that there are statistically significant differences for the significance level of α=0.05 between all the yarn properties of 100% wool compact and conventional ring yarns. In terms of other yarns spun with 45% wool/50% PET, 50% wool/50% PAN and 100% PAN raw materials, these differences have not been found statistically significant for all yarn parameters. 100% wool compact yarns have better tenacity, elongation at break (%), evenness, thinand thick places, nep values and hairiness values than conventional ring yarns. But only 50% wool/50% PAN compact yarns have better tenacity and lower yarn evenness (Uster CV%) values than conventional ring yarns, and their differences were found to be statistically significant for α=0.05. In 100% PAN yarns, the difference of Uster CV% and I.P.I. values between two spinning systems were not found to be statistically significant for α=0.05. According to these results, the difference of yarn parameters between two spinning systems is clearer when natural fibres are used. In addition, the difference is clearer when a high percentage of natural fibre is used in the blend, also.

Another comparison was made between two yarn counts, and it was seen that there was also a significant difference between the two different yarn numbers. In the fine yarn counts, the number of fibres in the yarn cross-section is more important than the coarser yarn counts, because fine yarn has fewer fibres than coarser yarn in the yarn cross-section. In compact spinning, the drafted fibres emerging from the nip line of the drafting arrangement’s front roller are condensed in a line. In this way, almost all the drafted fibres are incorporated into the yarn body. Thus, fine compact yarns have more advantages than fine conventional ring yarns.

In addition, the compact yarns at low twist level have better yarn properties values than conventional yarns at high twist level. For example, in 25 tex yarns produced with 50% wool/50% PAN, conventional ring yarn tenacity values were 8.25 cN/tex for αtex=1675, and 9.81 cN/tex for αtex=2055. On the other hand, the compact yarn tenacity value was 9.80 cN/tex for αtex=1675.

However, the most important advantage of the compact spinning technique is the reduction in yarn hairiness. When we looked at the laboratory results for all material types, the compact spun yarns have less yarn hairiness than the conventional ring-spun yarns. This reduction in yarn hairiness brings new opportunities for producing different products in the future. Weaving and knitting sectors can profit from the compact spinning system.

n Conclusions

§ Fine compact yarns have more advantages than fine conventional ring yarns.

§ The most important advantage of the compact spinning technique is a reduction in yarn hairiness, which brings new opportunities for the production of different products in the future. The weaving and knitting branches can profit from the compact spinning system.

§ Although the compact spinning technique brings advantages regarding quality and production, we must bear in mind that the investment cost of the compact spinning machines are higher than the conventional ring spinning machines, and the cost of compact yarn is higher than the conventional ones, also. Consequently, worsted compact yarns are preferred for high quality and expensive products, especially for woven fabrics in the market.

§ Investigations into compact yarn’s advantages in downstream processing (weaving, knitting, dyeing, etc.) should be still continued.

References

1. Hechtl R., Melliand International, 1996, Vol.1, p.12-13.

2. Kadoğlu H., Melliand International, 2001, Vol. 7, p. 23-25.

3. Stalder H., Melliand English, 2000, Vol.3, p. E26-E27.

4. Olbrich A., Melliand English, 2000, Vol. 3, p. E27-E28.

5. Artzt P., International Textile Bulletin, 1997, Vol. 2, p. 41-48.

6. Campen W., Melliand English, 2002, Vol. 6, p. E82-E83.

7. Anonym, Spinnovation, 2001, September, p. 6-7.

8. Anonym, Spinnovation, 2000, December, p. 18-19.

9. Anonym, Spinnovation, 2000, July, p. 8-11.

10. Nicolic M., Lesjak F, Stritof A., TEKSTIL, 2000, July, 49(7), p. 349-356.

11. Nikolic M, Stjepanovic Z, Lesjak F, Stritof A., Fibres & Textiles in Eastern Europe, Vol. 11, No 4 (43), 2003, p. 30-35.

12. Celik P., M.Sc. Thesis, The Institute of Natural and Applied Sciences, Ege University, Izmir-Turkey, 2002, September.

Figure 1. Conventional and compact ring spinning yarns (Spinnovation 7/2000) [9].

Table 1. Experimental plan.

|

Parameter |

Longstapel Tester PR135 conventional ring spinning machine |

Longstapel Tester PR135 compact ring spinning machine |

Longstapel Tester PR135 conventional ring spinning machine |

Longstapel Tester PR135 compact ring spinning machine |

|

|

100% wool (21.3 micron, max. fibre length 130 mm) |

Yarn count, tex |

19 |

19 |

25 |

25 |

|

Twist coefficient, αtex |

2530, 2685, 2845, 3160 |

2530, 2685, 2845, 3160 |

2530, 2685, 2845, 3160 |

2530, 2685, 2845, 3160 |

|

|

Roving count, tex |

2.3 |

2.3 |

2.3 |

2.3 |

|

|

Spindle speed, rpm |

9200 |

9200 |

9200 |

9200 |

|

|

45%wool/50% PET (wool 22 micron/PET 1.65 dtex) |

Yarn count, tex |

19 |

19 |

25 |

25 |

|

Twist coefficient, αtex |

2530, 2685, 2845, 3160 |

2530, 2685, 2845, 3160 |

2530, 2685, 2845, 3160 |

2530, 2685, 2845, 3160 |

|

|

Roving count, tex |

2.1 |

2.1 |

2.1 |

2.1 |

|

|

Spindle speed, rpm |

9200 |

9200 |

9200 |

9200 |

|

|

50%wool/50% PAN (wool 23.5 micron/PAN 3.3 dtex) |

Yarn count, tex |

25 |

25 |

36 |

36 |

|

Twist coefficient, αtex |

1675, 1900, 2055, 2210 |

1675, 1900, 2055, 2210 |

1675, 1900, 2055, 2210 |

1675, 1900, 2055, 2210 |

|

|

Roving count, tex |

2 |

2 |

2 |

2 |

|

|

Spindle speed, rpm |

9200 |

9200 |

9200 |

9200 |

|

|

100% PAN (3.3 dtex) |

Yarn count, tex |

25 |

25 |

36 |

36 |

|

Twist coefficient, αtex |

1675, 1900, 2055, 2210 |

1675, 1900, 2055, 2210 |

1675, 1900, 2055, 2210 |

1675, 1900, 2055, 2210 |

|

|

Roving count, tex |

2.1 |

2.1 |

1.3 |

1.3 |

|

|

Spindle speed, rpm |

9200 |

9200 |

9200 |

9200 |

|

Table 2. Yarn hairiness test results of 100% wool yarns.

|

Measured yarn properties |

100% wool 25 tex yarn |

100% wool 25 tex yarn |

||||||||

|

αtex 2530 |

αtex 2690 |

αtex 2845 |

αtex 3160 |

αtex 2530 |

αtex 2690 |

αtex 2845 |

αtex 3160 |

|||

|

Uster Tester 3 |

Hairiness (H) |

conventional |

6.38 |

6.14 |

5.99 |

5.54 |

6.97 |

6.61 |

6.38 |

6.06 |

|

compact |

4.71 |

4.52 |

4.34 |

4.02 |

4.82 |

4.64 |

4.49 |

4.29 |

||

|

sh |

conventional |

1.85 |

1.75 |

1.73 |

1.60 |

1.86 |

1.76 |

1.71 |

1.62 |

|

|

compact |

1.30 |

1.26 |

1.20 |

1.07 |

1.26 |

1.22 |

1.16 |

1.09 |

||

|

Zweigle G 566 Hairiness Tester |

Class 1 mm |

conventional |

7828 |

8458 |

8493 |

8336 |

9149 |

9617 |

9724 |

9530 |

|

compact |

4723 |

4930 |

5062 |

5288 |

5773 |

5934 |

5687 |

5407 |

||

|

Class 2 mm |

conventional |

2240 |

2400 |

2420 |

2267 |

2646 |

2674 |

2662 |

2501 |

|

|

compact |

1240 |

1255 |

1276 |

1239 |

1431 |

1424 |

1356 |

1290 |

||

|

Class 3 mm |

conventional |

964 |

1082 |

1062 |

938 |

1151 |

1173 |

1085 |

1044 |

|

|

compact |

418 |

412 |

419 |

374 |

505 |

455 |

430 |

387 |

||

|

Class 4 mm |

conventional |

503 |

573 |

553 |

479 |

609 |

607 |

550 |

481 |

|

|

compact |

175 |

155 |

143 |

133 |

187 |

171 |

165 |

125 |

||

|

Class 6 mm |

conventional |

162 |

185 |

180 |

157 |

189 |

169 |

139 |

158 |

|

|

compact |

25 |

30 |

28 |

19 |

35 |

27 |

29 |

19 |

||

|

Class 8 mm |

conventional |

99 |

126 |

124 |

109 |

98 |

93 |

65 |

128 |

|

|

compact |

11 |

12 |

12 |

10 |

12 |

12 |

10 |

9 |

||

|

Class 10 mm |

conventional |

47 |

61 |

63 |

53 |

36 |

46 |

25 |

71 |

|

|

compact |

3 |

2 |

2 |

3 |

3 |

3 |

3 |

4 |

||

|

S3-value (∑≥3 mm) |

conventional |

1814 |

2086 |

2041 |

1779 |

2110 |

2130 |

1887 |

1966 |

|

|

compact |

634 |

613 |

606 |

540 |

744 |

670 |

637 |

545 |

||

Table 3. Test results and statistical results of 50% Wool/50% PAN yarns (*statistically significant for α=0.05).

|

Measured yarn properties |

50% wool/50% PAN 25 tex yarn |

||||

|

αtex 1675 |

αtex 1900 |

αtex 2055 |

αtex 2210 |

||

|

Yarn tenacity, cN/tex |

conventional |

8.25 |

9.39 |

9.81 |

10.21 |

|

compact |

9.80 |

10.66 |

11.12 |

11.23 |

|

|

Statistical evaluation |

significance |

0.000* |

0.000* |

0.000* |

0.002* |

|

Uster CV% |

conventional |

17.22 |

16.93 |

16.90 |

16.87 |

|

compact |

16.42 |

16.25 |

16.06 |

16.04 |

|

|

Statistical evaluation |

significance |

0.001* |

0.000* |

0.000* |

0.000* |

|

Thin places/1000 m |

conventional |

96 |

75 |

92 |

80 |

|

compact |

60 |

44 |

48 |

55 |

|

|

Statistical evaluation |

significance |

0.002* |

0.001* |

0.000* |

0.034* |

|

Thick places/1000 m |

conventional |

31 |

21 |

22 |

18 |

|

compact |

13 |

14 |

9 |

7 |

|

|

Statistical evaluation |

significance |

0.009* |

0.028* |

0.013* |

0.006* |

|

Hairiness (H) |

conventional |

8.18 |

6.89 |

6.62 |

6.14 |

|

compact |

5.83 |

5.34 |

4.80 |

4.73 |

|

|

Statistical evaluation |

significance |

0.001* |

0.000* |

0.000* |

0.000* |

|

Zweigle hairiness S3 |

conventional |

1897 |

1646 |

1634 |

1553 |

|

compact |

955 |

729 |

631 |

607 |

|

|

Statistical evaluation |

significance |

0.000* |

0.000* |

0.000* |

0.002* |

Figure 3. Uster CV% values of 45% wool/55% PET yarns.

Figure 2. Thin places values of 100% wool yarns.

Figure 4. Yarn tenacity values of 45% wool/55% PET yarns.

Figure 5. Yarn tenacity values of 100% PAN yarns.

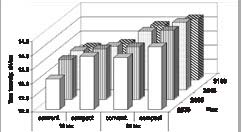

Figure 6. Zweigle hairiness S3 values of 50% Wo/50% PAN yarns.

Received 15.03.2004 Reviewed 02.07.2004

8th International Conference

ArchTex

‘High Technologies in Textiles’

18-20 September 2005, Kraków, Poland

Organiser: Institute of Textile Architecture (IAT), Łódź, Poland.

International Scientific Committee

President - Professor Iwona Frydrych, Ph.D., D.Sc. (IAT, Łódź, Poland).

Members: Prof. Mario de Araújo, Ph.D., D.Sc. (University of Minho, Portugal); Kim Gandhi, Ph.D. (UMIST, Manchester, Great Britain); Urania Kechagia, Ph.D. (NAGREF, Thessaloniki, Greece); Prof. Jiři Militký, Ph.D., D.Sc., Eur. Ing. (Technical University of Liberec, Czech Republic); Prof. Edward Rybicki, Ph.D., D.Sc. (IAT, Łódź, Poland); Prof. Arvydas Vitkauskas, Ph.D., D.Sc. (Kaunas University of Technology, Lithuania).

Organising Committee

President - Andrzej Kluka, M.Sc. Secretary - Małgorzata Skrobecka, M.Sc.

Important dates:

§ Submission of abstract - 15 January 2005

§ Acceptance of paper and instructions for preparing paper - 15 February 2005

§ Submission of full papers - 31 March 2005.

Scientific and technical topics

§ The latest worlds’ advanced technologies of: production of man-made fabrics, spinning, finishing, knitting, clothing, and nonwovens.

§ Information technology in textiles.

§ Nanotechnology in textiles.

§ Technical textiles.

§ Medtextiles.

§ Quality assurance systems in the textile industry.

§ Environment protection and ecology.

§ Protective clothing.

For more information please contact:

Institute of Textile Architecture

ul. Piotrkowska 276, 90-950 Łódź, Poland

Tel.: (48-42) 682-59-29 Fax (48-42) 684-23-00

E-mail: iat@iat.com.pl Web: www.iat.com.pl